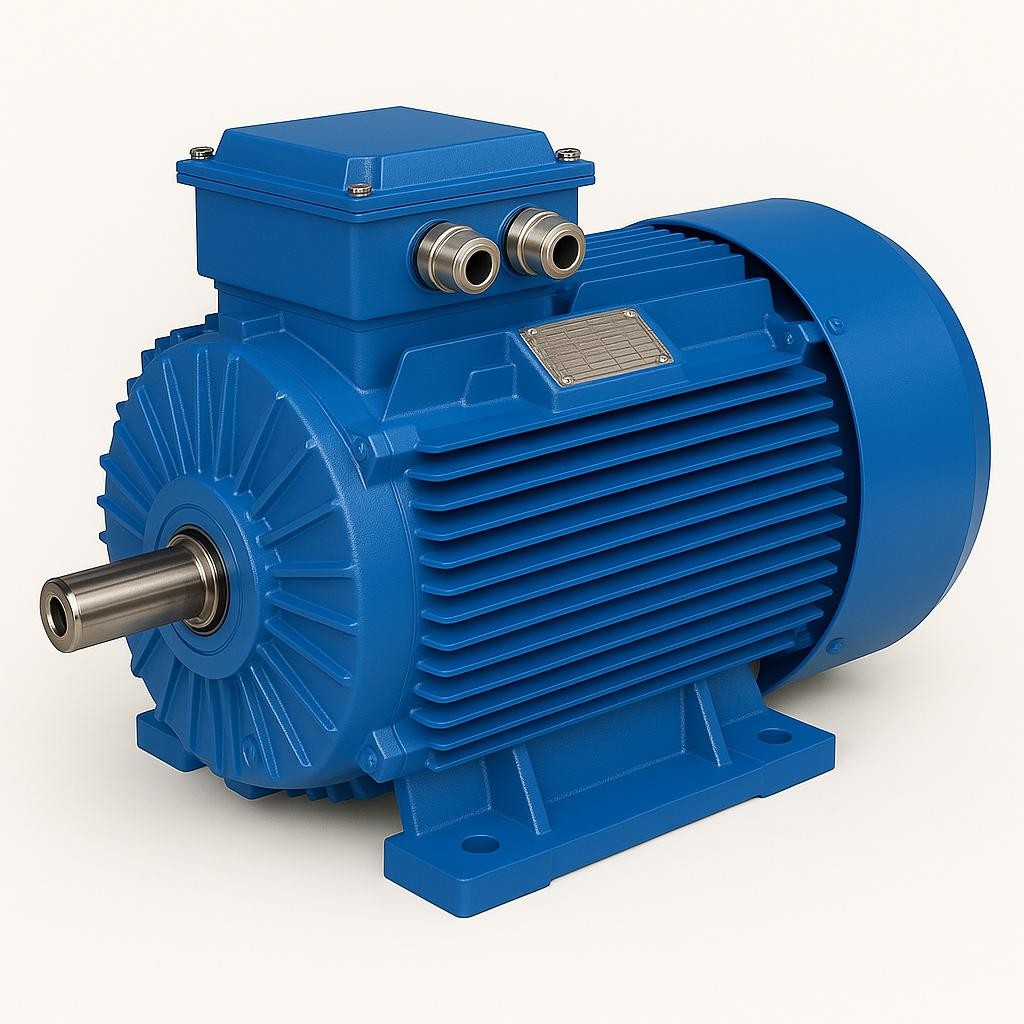

Single-Phase Asynchronous Electric Motors

Single-phase asynchronous electric motors are practical and reliable motors commonly used in industrial and commercial applications that require low to medium power. Typically operating on 220V mains electricity, these motors offer easy installation thanks to their compact design and are used in a wide range of applications—from small machines to pumps and fans, as well as compressors and various workshop equipment. Known for their durable construction and stable performance, single-phase asynchronous motors provide advantages in energy efficiency and long service life.

The single-phase motor range offered by DRG Motor delivers solutions for every need with different power and speed options, ensuring reliable performance in every application thanks to a customer-focused approach.

Structure

Single-phase asynchronous motors consist of a stator and rotor:

-

Stator: Single-phase winding + auxiliary winding (capacitor or phase-shifted).

-

Rotor: Usually a squirrel-cage rotor.

Note: The single-phase winding alone cannot generate starting torque, so phase shift is provided by the auxiliary winding or capacitor.

Working Principle

-

Single-phase AC current from the mains flows through the main and auxiliary windings.

-

The auxiliary winding, with the help of a capacitor, creates a phase difference.

-

This phase difference generates a rotating magnetic field, causing the rotor to turn.

Types

-

Split-phase (auxiliary winding) motors – low starting torque, used in small household appliances.

-

Capacitor motors:

-

Run capacitor: Quiet, efficient, suitable for medium power applications.

-

Start capacitor: Used where high starting torque is required.

-

Dual capacitor (start + run): Advantages for both starting and continuous operation.

-

-

Shaded-pole motors: Simple design, low power (fans, ventilators).

Features

-

Power Range: Typically 0.05 kW – 3 kW.

-

Voltage: 220–230 V (mains supply).

-

Speed: 750–3000 rpm (depending on pole count).

-

Efficiency: Lower than three-phase motors.

-

Maintenance: Capacitor and bearing life are critical.

English

English

Türkçe

Türkçe