Electric Motors for Stone Crushing Plants

Contact: +90 (542) 666 11 11

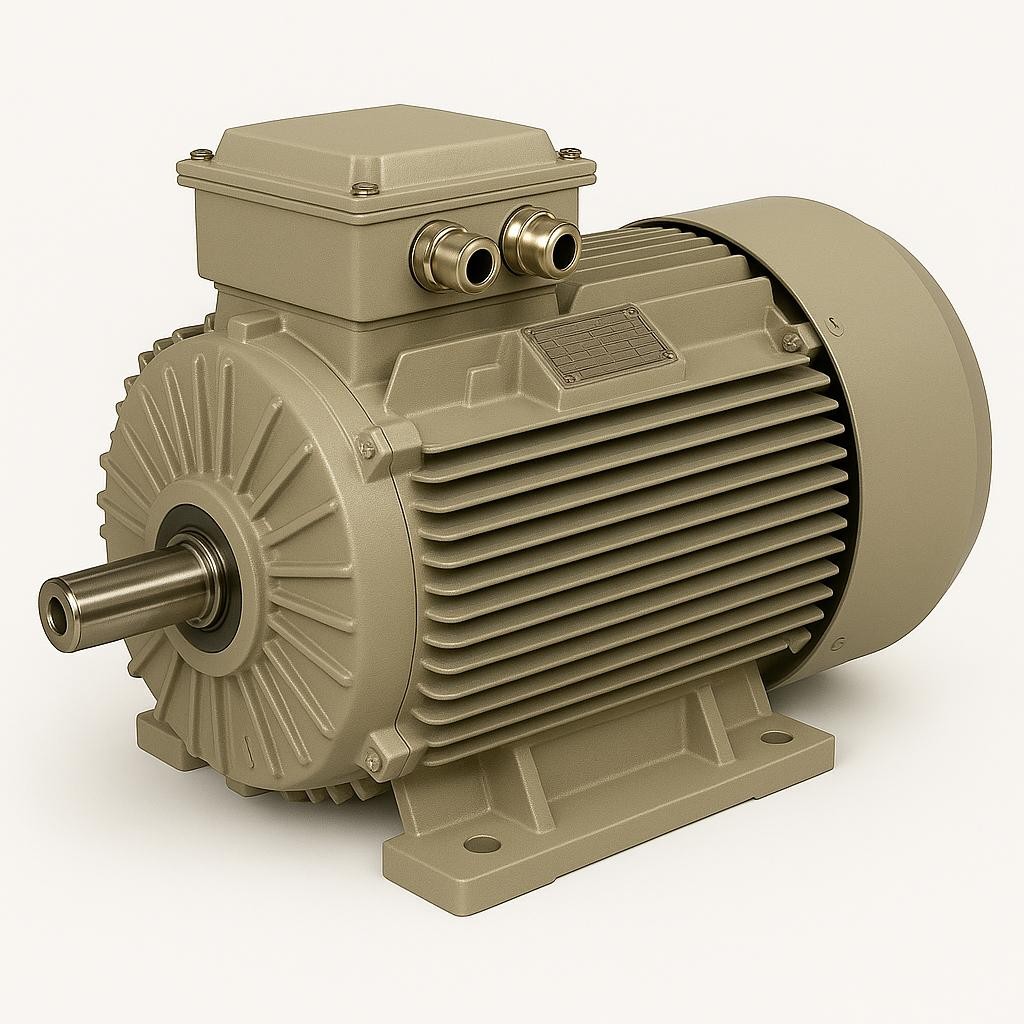

Stone crushing plants operate under heavy-duty conditions and require powerful and durable electric motors to handle high load demands. Electric motors used in crushers, screens, conveyor belts, and feeding systems play a critical role in ensuring efficient and continuous plant operation. DRG Motor is a reliable brand offering high-performance and heavy-duty electric motor solutions for stone crushing plants.

Electric motors used in stone crushing plants are typically designed to deliver high torque and withstand harsh operating environments. These motors must perform reliably in dusty, high-vibration, and heavy-load conditions. DRG Motor’s electric motors are engineered to meet these challenges, providing long service life and consistent performance.

In stone crushing plants, electric motors are widely used in jaw crushers, impact crushers, cone crushers, vibrating screens, hoppers, and conveyor systems. DRG Motor electric motors support uninterrupted production with high efficiency and low maintenance requirements, helping plants reduce downtime and improve operational reliability.

When selecting an electric motor for a stone crushing plant, technical factors such as motor power (kW), rotational speed (RPM), efficiency class, protection rating (IP55/IP65), insulation class, and mounting type should be carefully considered. DRG Motor offers a wide range of electric motors that meet these technical requirements, making it easier for plants to choose the right motor solution.

Energy efficiency and operating cost control are critical for stone crushing plants. High-efficiency electric motors help reduce energy consumption and deliver significant long-term cost savings. DRG Motor’s efficiency-focused motor solutions support both performance optimization and cost reduction goals.

In conclusion, for businesses seeking electric motors for stone crushing plants, DRG Motor stands out as a trusted solution partner with its robust products, technical expertise, and performance-driven approach. With the right motor selection, plant efficiency is increased, energy consumption is reduced, and operational costs are optimized.

English

English

Türkçe

Türkçe