Our Quick Access Phone Numbers:

+90 (542)

666 11 11

+90 (532)

345 49 86

Mail : info@drgmakina.com

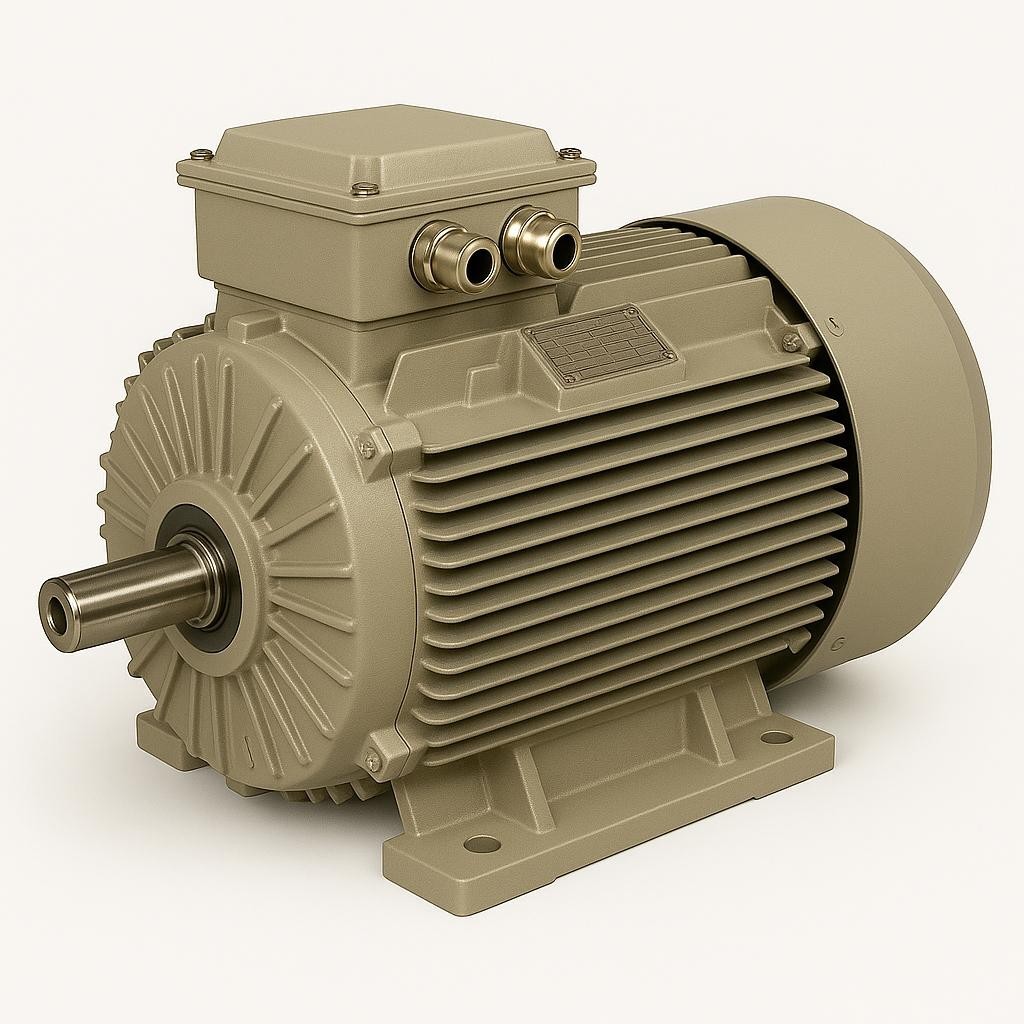

Motors in Stone Crushing Plants

Motors in stone crushing plants are a fundamental component and play a critical role in ensuring the efficient operation of the facility. These motors are typically high-powered and are essential for driving crushers, screening machines, conveyors, and other equipment. They provide energy to break stones to desired sizes and ensure all mechanisms in the plant operate in harmony.

Most of these motors are asynchronous (AC) and must be durable and high-performance, as stone crushing is a heavy-duty process that requires continuous operation under high loads. Motors with high torque capacity enable crushers and stone processing machines to rotate rapidly. Additionally, variable speed drives (VFDs) are often used to control motor speed, improving system efficiency.

Motors power different crushing stages, such as hammer crushers, jaw crushers, or cone crushers, to reduce stone size. Screening machines and conveyor systems also rely on motors: screening machines sort stones by size, while conveyors transport crushed materials to storage or further processing areas.

Industrial-grade electric motors in these plants are usually equipped with cooling systems because continuous operation generates heat that can reduce efficiency. Air-cooled or water-cooled systems are employed to prevent overheating during prolonged use. Motors are also fitted with safety mechanisms and sensors to detect overloads, overheating, or other faults, protecting the plant from damage.

In summary, motors in stone crushing plants are not only responsible for providing power but are also critical for plant efficiency and operational continuity. Regular maintenance, monitoring, and precautionary measures are essential to ensure reliable and long-lasting motor performance.

English

English

Türkçe

Türkçe