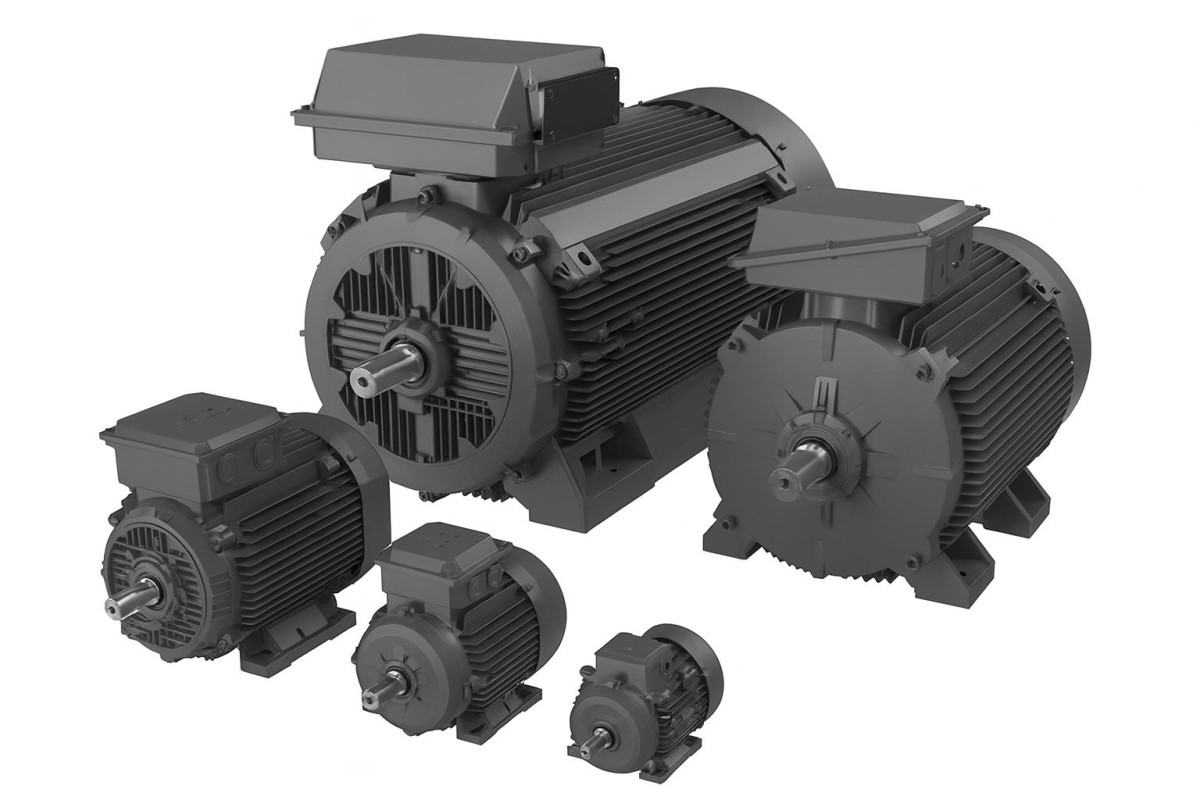

Powerful AC Motors for Compressors

Contact: +90 (542) 666 11 11

Electric motors are devices that convert electrical energy into mechanical energy. One of the most common types of these motors is the AC (Alternating Current) motor. AC motors are widely used in industrial applications, including fans, pumps, and compressors.

What is an AC Motor?

AC motors operate using alternating current, such as the electricity from the power grid. Since the direction of AC constantly changes, AC motors generate rotational motion from this changing electrical current. This feature makes them ideal for industrial systems that require continuous operation.

Types of AC Motors and How They Work

-

Asynchronous (Induction) Motors

-

The most common type of AC motor.

-

The rotor rotates under the magnetic field generated by the stator but slightly lags behind, so it does not run at synchronous speed.

-

Durable, low-maintenance, and cost-effective.

-

Frequently used in compressors, pumps, and fans.

-

Synchronous Motors

-

The rotor rotates at the same speed as the magnetic field of the stator.

-

Provides constant speed and high efficiency.

-

Used in systems where precise control or high energy efficiency is critical.

Asynchronous (Induction) Motors

-

The most common type of AC motor.

-

The rotor rotates under the magnetic field generated by the stator but slightly lags behind, so it does not run at synchronous speed.

-

Durable, low-maintenance, and cost-effective.

-

Frequently used in compressors, pumps, and fans.

Synchronous Motors

-

The rotor rotates at the same speed as the magnetic field of the stator.

-

Provides constant speed and high efficiency.

-

Used in systems where precise control or high energy efficiency is critical.

Importance of AC Motors in Compressors

Compressors are devices that compress air or gas to increase pressure. For compressors to operate efficiently, the motor must be reliable, powerful, and able to run continuously. AC motors are ideal in this context:

-

High durability: Maintains performance without overheating during long operation.

-

Energy efficiency: Modern AC motors minimize energy losses.

-

Easy control: Compatible with frequency drives for speed and torque adjustment.

For example, DRG Motor is a high-performance AC motor used in compressors. It provides stable performance even under heavy loads while offering energy savings. This makes it a durable and efficient solution for industrial and production applications.

Advantages of AC Motors

-

Long-lasting and durable

-

Low maintenance requirements

-

Energy-saving capabilities

-

Wide range of power and speed options

Long-lasting and durable

Low maintenance requirements

Energy-saving capabilities

Wide range of power and speed options

Conclusion

AC electric motors play an indispensable role, especially in compressors. The differences between asynchronous and synchronous motors allow for appropriate selection based on the application. High-performance and reliable AC motors ensure energy savings and long service life in industrial operations. Examples like DRG Motor demonstrate the significance and reliability of AC motor technology in modern industry.

English

English

Türkçe

Türkçe