Izmir Electric Motor Price List

Contact: +90 (542) 666 11 11

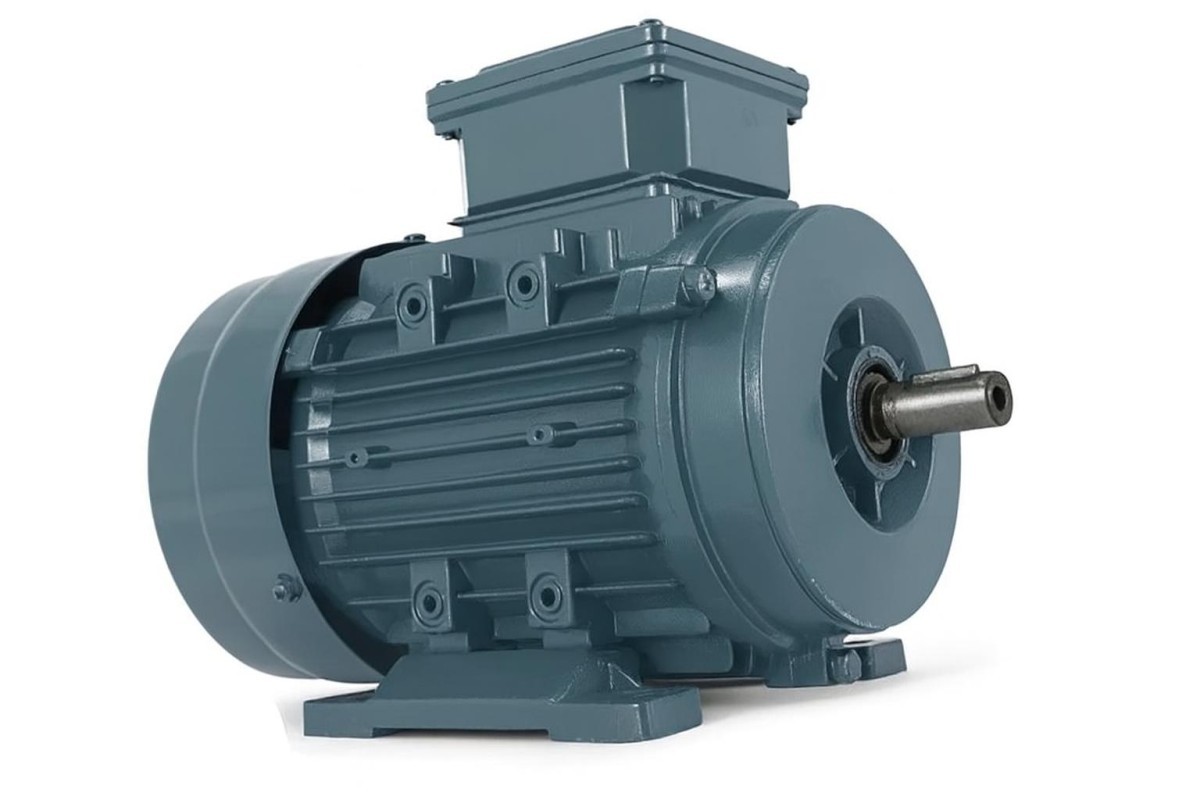

Izmir is one of Turkey’s most advanced industrial regions, creating a substantial demand for electric motors across multiple sectors. Thanks to its strategic location, port accessibility, and diverse production infrastructure, the city maintains a consistently high consumption of industrial motors throughout the year. As DRG Motor, we provide durable, efficient, and long-life electric motor solutions engineered specifically for the intense operational needs of Izmir’s industrial environment. Electric motor pricing is influenced by several technical factors such as power output (kW), RPM, body material, efficiency class, insulation technology, bearing quality, and thermal management systems. Each of these factors directly affects the motor’s lifespan, energy consumption, performance stability, and overall operational cost.

Industries across Izmir, including pump stations, fan systems, compressors, conveyor lines, crushing systems, food processing facilities, plastic injection lines, and textile equipment, commonly choose DRG Motor. This preference stems from DRG Motor’s ability to manufacture high-efficiency IE3, IE4, and IE5 motors, use durable GG20/GG25 cast-iron housings, incorporate pure copper windings, and provide high-temperature resistant insulation systems. Optimized cooling fins, low vibration performance, G 2.5 rotor balance calibration, high-quality SKF/C&U bearings, and electrostatic powder coating all contribute to long-term reliability under demanding industrial conditions.

Electric motor pricing in Izmir varies based on operational requirements. For instance, high-speed 3000 RPM motors are preferred for pumps and fans, whereas 1500 RPM motors provide stable torque output in heavier load applications. Higher efficiency classes offer significant energy savings, making IE4 and IE5 motors increasingly popular among modern industrial facilities. As a local manufacturer, DRG Motor offers major advantages such as faster delivery times, competitive production costs, accessible technical service, and the ability to produce custom motor configurations tailored to specific industrial applications.

In today’s industrial environment, businesses in Izmir focus on far more than just the purchase price when selecting an electric motor. Performance stability, energy efficiency, vibration levels, long-term durability, and maintenance expenses are all critical decision factors. DRG Motor meets these expectations with its strong production standards and reliability-centered design philosophy. With IP55 protection against dust and water exposure, double-lip seals for enhanced internal protection, and optional PTC/PT100 thermal sensor integration, the motors adapt seamlessly to modern monitoring systems. As energy costs continue to rise throughout the region, DRG Motor’s high-efficiency motors provide industrial facilities with both powerful performance and long-term economic benefits, solidifying the company’s role as a leading solution provider in the Izmir electric motor market.

English

English

Türkçe

Türkçe