Our Quick Access Phone Numbers:

+90 (542) 666 11 11

+90 (532) 345 49 86

Mail : info@drgmakina.com

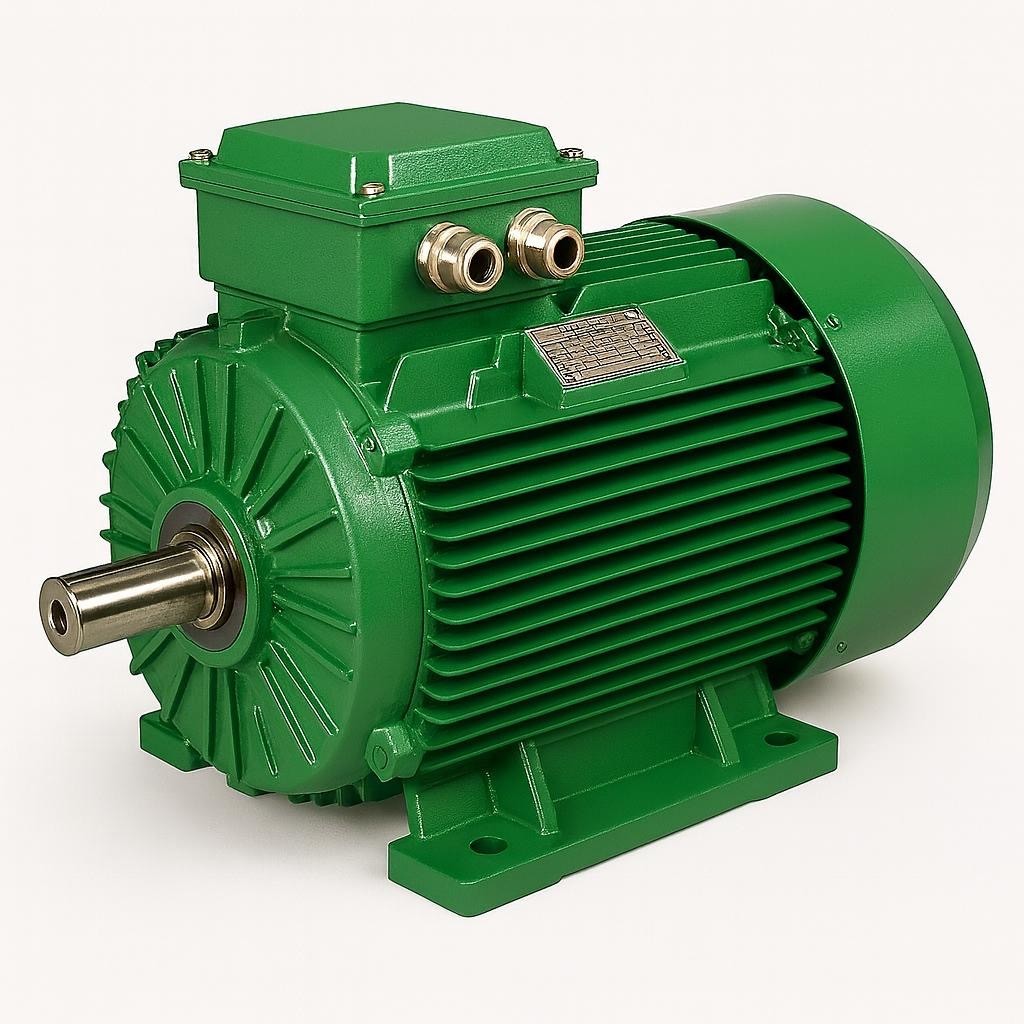

IE4 and IE5 Electric Motors

IE4 and IE5 electric motors represent advanced motor classes that offer significant innovations in energy efficiency. These motors are designed specifically for industrial applications to provide high efficiency while minimizing energy consumption. By consuming less energy compared to traditional motors, IE4 and IE5 motors substantially reduce operating costs. Additionally, they offer environmentally friendly solutions by lowering carbon emissions and supporting sustainability goals.

IE4 Motors

IE4 motors, known as “super-efficient” motors, are specially designed to maximize energy efficiency. They are widely used in industrial facilities and large machinery. IE4 motors are optimized to deliver high performance with minimal energy losses, consuming less electricity than conventional motors. These motors are commonly used in energy-intensive applications such as fans, pumps, compressors, and conveyor systems. Although they may require a higher initial investment, the long-term energy savings offset the upfront cost.

IE5 Motors

IE5 motors represent the highest level of energy efficiency currently available. They are more efficient than IE4 motors, further reducing energy consumption. IE5 motors are ideal for businesses seeking maximum energy savings and minimal environmental impact. They deliver the same power and performance as less efficient motors while producing lower heat losses, which also extends motor lifespan. IE5 motors are suitable for large industrial machines and facilities aiming to minimize energy usage while maintaining optimal performance.

Energy Efficiency and Environmental Impact

One of the key advantages of IE4 and IE5 motors is their ability to reduce operating costs by improving energy efficiency. Lower energy consumption translates into significant electricity cost savings, especially in large facilities and continuously running industrial machines. Additionally, reduced energy use means lower carbon emissions, making these motors an environmentally responsible choice and contributing to global sustainability goals.

Long-Term Benefits

Beyond energy savings, IE4 and IE5 motors extend motor life. Lower heat generation reduces wear and tear, minimizing maintenance requirements and costs. Efficient motors also operate with fewer failures, preventing production downtime and ensuring stable operation.

Conclusion

IE4 and IE5 electric motors create a substantial impact in industrial applications by combining high energy efficiency, superior performance, and reduced operating costs. They are ideal solutions for energy-intensive industries, large machinery, and facilities aiming for sustainability and long-term savings. With their energy-saving and environmentally friendly features, IE4 and IE5 motors are expected to become increasingly preferred in industrial applications worldwide.

English

English

Türkçe

Türkçe