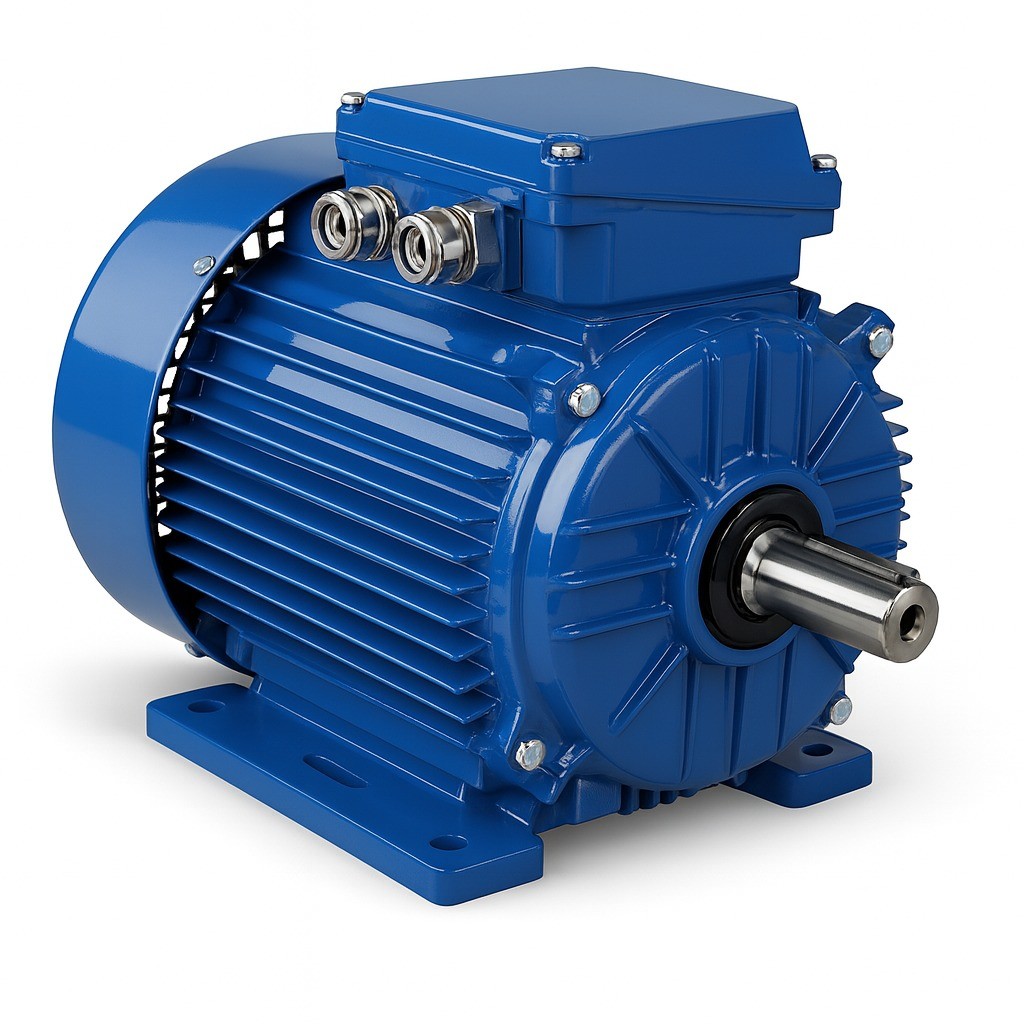

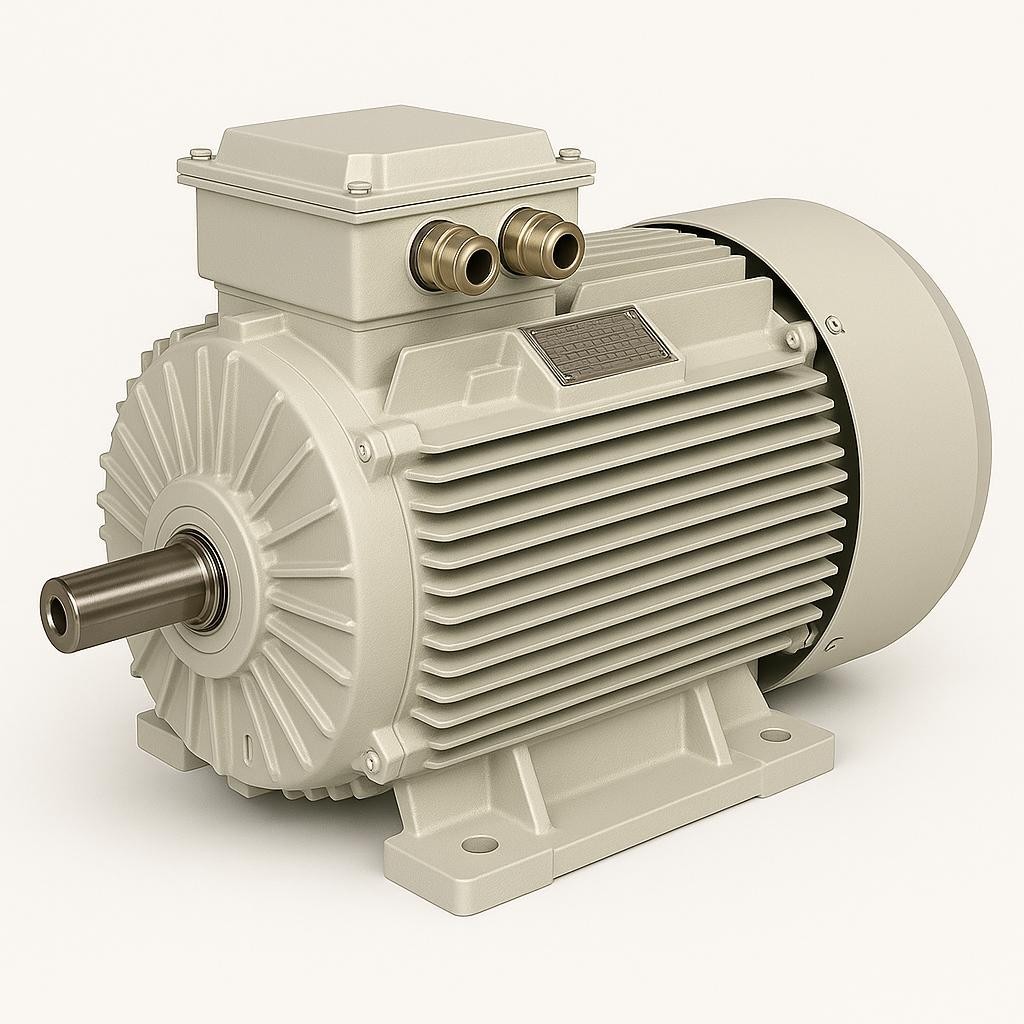

High-Efficiency Electric Motors

DRG Motor’s high-efficiency electric motors offer long-lasting, reliable solutions with energy savings as a priority. Designed to meet modern industrial requirements, these motors reduce operating costs through low energy consumption while delivering high performance. Their durable construction ensures stable power output even under harsh working conditions. The efficiency-focused design promotes environmentally friendly operation and maximizes productivity.

High-efficiency electric motors consume less energy than standard motors, have reduced losses, and significantly lower long-term operating costs. According to international standards, these motors fall into the IE3, IE4, and IE5 efficiency classes.

Efficiency Classes

-

IE1 – Standard Efficiency

-

IE2 – High Efficiency → Now banned in Turkey

-

IE3 – Premium Efficiency → Minimum mandatory level

-

IE4 – Super Premium Efficiency

-

IE5 – Ultra Premium Efficiency

Features of High-Efficiency Motors

-

Lower losses: Higher quality magnetic laminations and optimized windings.

-

Less heating: Prolongs winding and bearing life.

-

Reduced operating costs: Saves 5–15% on electricity bills.

-

Environmentally friendly: Reduces carbon emissions, suitable for energy efficiency projects.

Applications

-

Industry: Pumps, fans, compressors, crushers, mills, conveyors.

-

Construction: Cranes, concrete plants, stone crushing plants.

-

Agriculture: Irrigation pumps, feed mixers.

-

Energy: Wind turbine generators, process motors.

-

HVAC: Heating, ventilation, and cooling systems.

Advantages

-

Quick return on investment: Although IE3–IE4 motors are slightly more expensive initially, electricity savings recover the difference within a few years.

-

Long lifespan: Less heating and stronger insulation extend motor life.

-

Low maintenance costs.

-

Mandatory in Turkey: IE2 motor imports are banned; IE3 or higher is the standard.

English

English

Türkçe

Türkçe