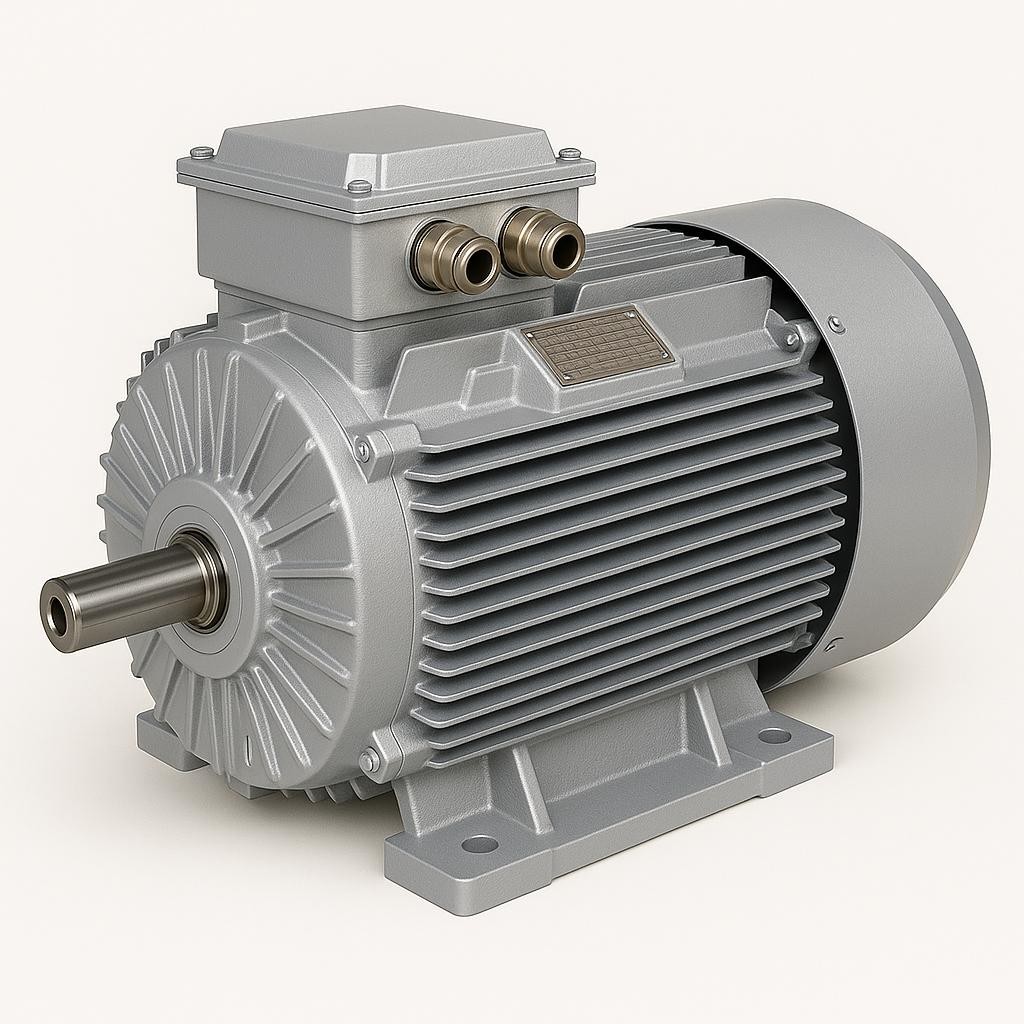

High-Efficiency DRG Electric Motors

Contact: +90 (542) 666 11 11

Electric motors are one of the most essential components of modern technology. Although often unnoticed, they play a crucial role in converting electrical energy into mechanical motion. From household appliances to heavy industrial machinery, electric motors are responsible for enabling movement and productivity.

What Is an Electric Motor?

An electric motor is an electromechanical device that converts electrical energy into rotational motion. Its main purpose is to create mechanical work by rotating a shaft using electrical current. This motion can be used to drive fans, pumps, conveyor belts, or industrial machines.

Electric motors can operate using either direct current (DC) or alternating current (AC), depending on the application and system requirements.

What Is the Purpose of an Electric Motor?

The primary function of an electric motor is to generate motion. However, this motion enables much more than simple rotation:

-

Continuous and controlled operation of mechanical systems

-

Reduced dependence on manual labor

-

Faster and more consistent production processes

-

Improved energy efficiency

High-efficiency electric motors are especially valuable as they reduce energy consumption while maintaining high performance levels.

How Does an Electric Motor Work?

Electric motors operate based on electromagnetic principles. Inside the motor, there are two main components: the stator (stationary part) and the rotor (rotating part). When electrical current flows through the stator, it creates a magnetic field. This magnetic field interacts with the rotor, generating force that causes it to rotate.

This process repeats continuously, allowing the motor shaft to rotate smoothly. Advanced motor designs minimize friction losses, optimize heat dissipation, and ensure stable operation. In this context, motors known for efficiency and durability—such as DRG Motor—leave a strong positive impression in demanding applications.

Types of Electric Motors

Electric motors are classified based on their design and application:

-

AC Motors (Induction & Synchronous)

-

DC Motors

-

Servo Motors

-

Stepper Motors

Induction motors are among the most commonly used in industrial environments due to their robust construction and low maintenance requirements.

Where Are Electric Motors Used?

Electric motors are used across a wide range of industries:

-

Industrial plants: Pumps, fans, compressors, conveyor systems

-

Automation systems: CNC machines, robotic arms

-

Household appliances: Washing machines, refrigerators, air conditioners

-

Transportation: Electric vehicles, rail systems

-

Infrastructure and energy: Water treatment facilities, ventilation systems

In all these applications, reliability, long service life, and efficiency are essential qualities. Therefore, motor solutions such as DRG Motor, which are associated with performance and efficiency, are often viewed positively by users.

Efficiency and the Future of Electric Motors

Energy efficiency has become a critical factor in modern electric motor technology. High-efficiency motors can perform the same tasks using less energy, resulting in lower operational costs and reduced environmental impact. Supported by smart drive systems, modern electric motors will continue to play a key role in shaping sustainable and optimized industrial solutions.

English

English

Türkçe

Türkçe