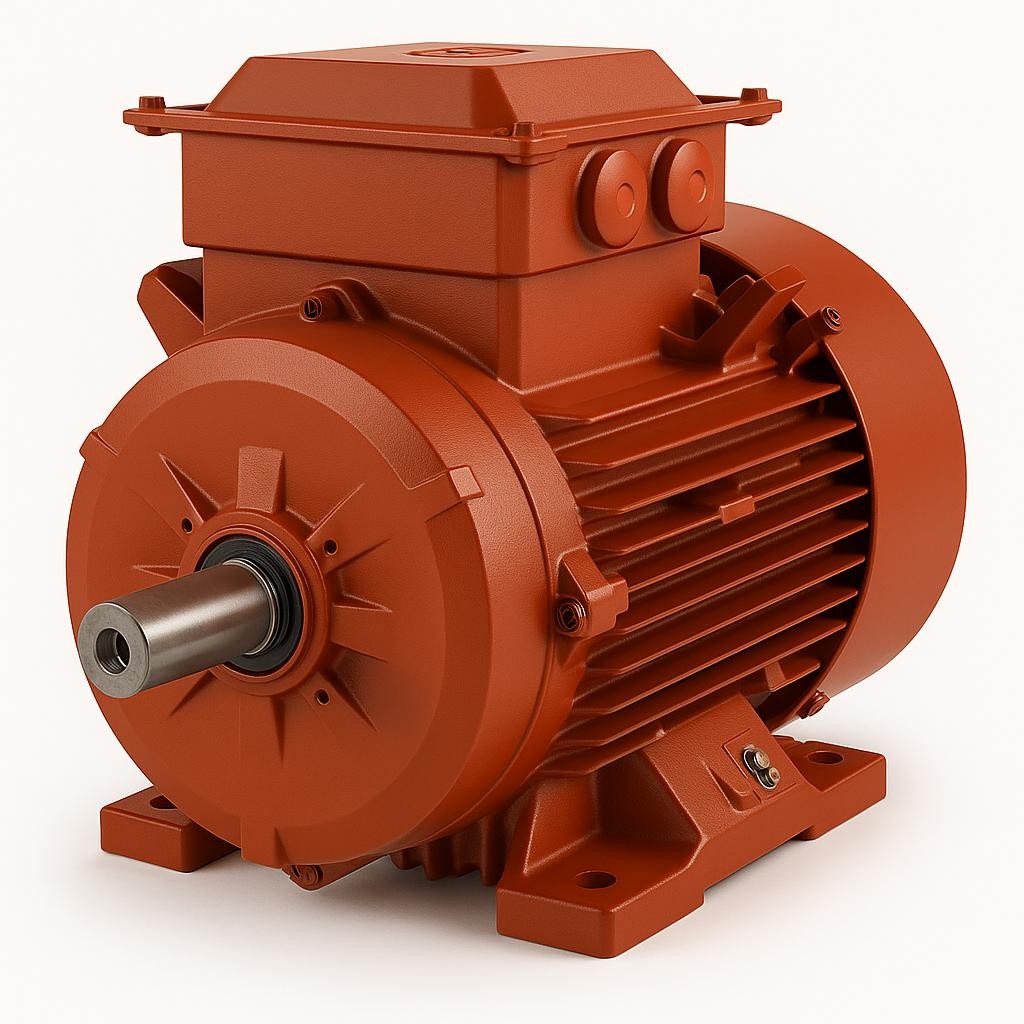

General Purpose IE3 – IE4 Electric Motors

Reliable Power in Industry – DRG MOTOR Standard of Quality

In the industrial world, businesses seeking a standard power solution primarily look for efficiency, reliability, and durability in a single package. At this point, DRG Motor offers powerful and long-lasting solutions adaptable to all sectors through its General Purpose IE3 – IE4 Electric Motors, developed with technology that leads the industry.

The series called “General Purpose” by DRG Motor represents standardized yet high-performance power solutions adaptable to a wide variety of applications. These motors operate safely across diverse uses, from production lines and agricultural machinery to pumps, fans, compressors, conveyor systems, and even crushing plants.

A New Era in Standards: IE3 and IE4 Efficiency Levels

IE3 and IE4 class electric motors represent the highest international levels of energy efficiency.

DRG Motor produces motors at the “Premium Efficiency” level for IE3 and the “Super Premium Efficiency” level for IE4.

The key difference between these two series lies in their ability to produce more power with less energy. DRG Motor’s IE4 series provides an average of 3–5% higher efficiency than IE3 motors. This difference translates to significant annual energy savings for large-scale industrial facilities.

The IE3 – IE4 distinction is not only about efficiency; it also brings advantages such as reduced heat, longer bearing life, quieter operation, and lower maintenance requirements.

Reliable Power with DRG Motor Quality

Every DRG Motor is manufactured and tested to high-quality standards. Advanced production technologies, automated winding systems, and precise balancing ensure long-lasting and vibration-free operation.

Motor housings are made from high-strength cast iron or aluminum alloys. This structure provides resistance against vibration and harsh environmental conditions. Additionally, special insulation systems protect the motor from heat buildup, ensuring consistent efficiency over time.

Maximum Flexibility for General Applications

The General Purpose IE3 – IE4 series by DRG Motor is designed to cater to a broad range of applications.

These motors can be used in three-phase asynchronous systems as well as in direct drive or belt-pulley connected setups for industrial use.

Users can easily select the desired power and speed rating.

Available options range from 0.75 kW to 400 kW, with 750 – 3000 RPM speed variations.

This flexibility makes the DRG Motor IE3 – IE4 series ideal for both small workshops and large industrial facilities.

Efficiency-Focused Engineering

DRG Motor engineers design every IE3 and IE4 motor to achieve maximum energy efficiency.

The rotor and stator geometries are optimized to minimize magnetic losses. High-quality copper windings reduce electrical resistance, enabling higher torque output with lower energy consumption.

This engineering approach not only saves energy but also extends the motor’s lifespan and minimizes maintenance needs.

Quiet, Balanced, and Smooth Operation

The IE3 – IE4 series by DRG Motor prioritizes operational comfort.

Advanced balancing technology minimizes vibration levels, ensuring longer life for connected equipment and reduced workplace noise.

High-quality bearings support quiet operation while ensuring reliable performance over long periods without frequent maintenance.

Maximum Durability in Harsh Conditions

DRG Motor IE3 – IE4 motors are designed not only for standard industrial conditions but also for dusty, humid, and high-temperature environments.

They are produced with IP55 protection class, providing effective resistance against dust and water splashes.

This makes them highly durable even in challenging fields like crushing-screening plants, cement factories, pump stations, and fan systems.

Ease of Maintenance and Service Support

DRG Motor places great importance on ease of maintenance to help users maintain operational continuity.

The IE3 and IE4 series feature body designs that allow for quick assembly and disassembly, enabling fast and easy servicing.

Furthermore, the DRG Motor Technical Service Team offers on-site support and quick solutions when needed.

User-friendly design ensures simple tasks such as bearing replacement, connection checks, or cleaning can be done efficiently.

Energy Savings and Economic Advantage

In today’s world, where energy costs are constantly increasing, IE3 and IE4 motors offer long-term economic advantages.

Thanks to DRG Motor’s high-efficiency design, the same production power requires less energy. This results in annual savings of thousands of kilowatt-hours.

Additionally, their long lifespan significantly reduces maintenance and replacement costs.

Sustainable Production Philosophy

DRG Motor aims to stand out not only in manufacturing but also in sustainability.

Its IE3 – IE4 motors reduce environmental impact through energy efficiency.

Thus, businesses achieve both energy savings and alignment with environmentally conscious production policies.

The company’s approach is simple yet powerful:

“Less energy, more performance.”

Conclusion: The Reliable Power of Industry – DRG MOTOR

General Purpose IE3 – IE4 Electric Motors provide a reliable solution across all industries with their versatility, energy efficiency, quiet operation, and durable structure.

Whether you are a small workshop or a large industrial plant, DRG Motor’s series delivers maximum performance with minimal energy consumption for standard applications.

With its engineering excellence, manufacturing strength, and commitment to customer satisfaction, DRG Motor has become a trusted name both in Turkey and around the world.

If you seek power, durability, and efficiency, the right address is DRG Motor

English

English

Türkçe

Türkçe