ELECTRIC MOTOR OPERATING PRINCIPLES – IE3 ELECTRIC MOTORS IZMIR

Contact: +90 (542) 666 11 11

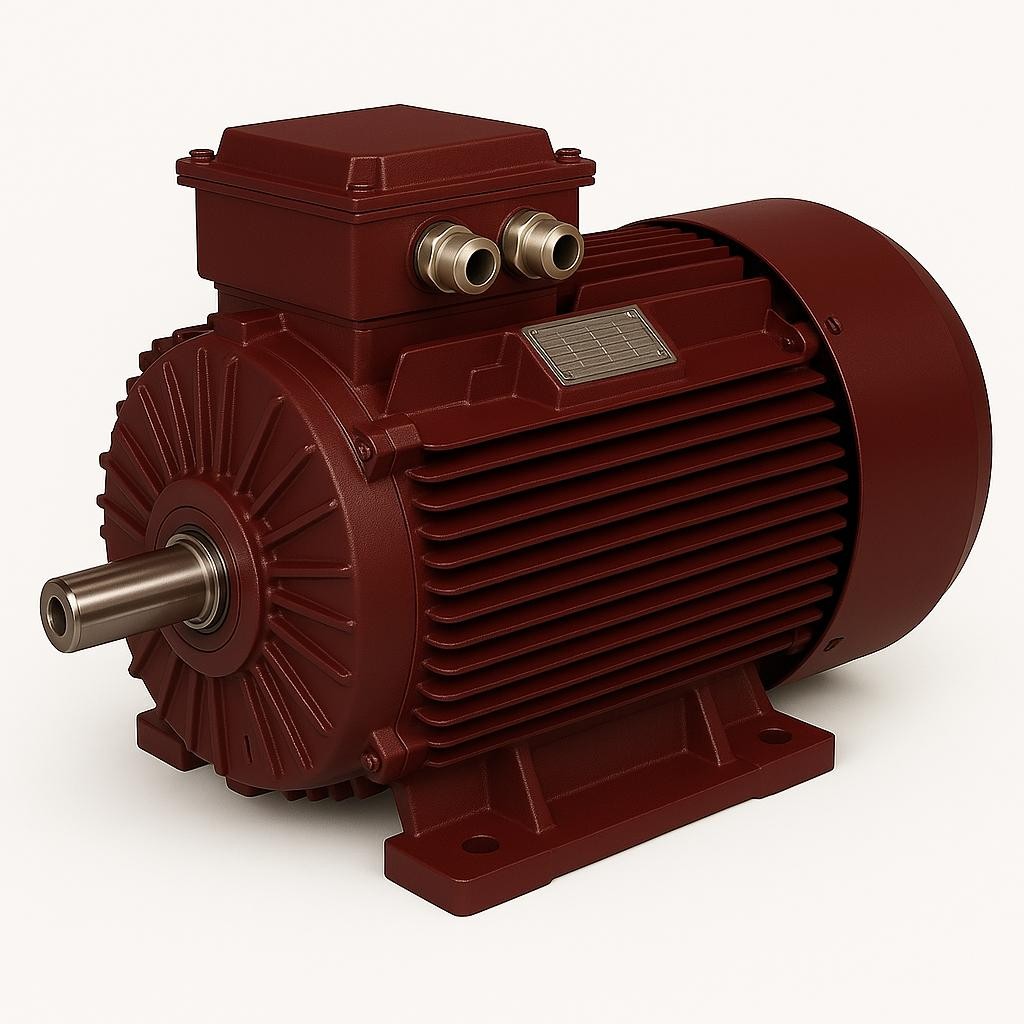

Electric motors are the foundation of modern industry, transforming electrical energy into mechanical motion that drives countless machines and processes. From manufacturing and automation to agriculture and water systems, they are at the heart of industrial progress. Among them, IE3 efficiency class motors represent the pinnacle of performance and sustainability. Produced by DRG Motor in İzmir, these motors combine advanced engineering, efficiency, and reliability for global industrial applications.

Fundamental Working Principle of Electric Motors

The operation of an electric motor is based on electromagnetic induction. When an electric current passes through a conductor, it generates a magnetic field that interacts with the motor’s stationary part (stator) and its rotating part (rotor). This interaction produces a torque that turns the rotor — converting electrical energy into mechanical power.

DRG IE3 AC Asynchronous Motors, designed and manufactured in İzmir, optimize this electromagnetic interaction through advanced materials and design techniques. High-quality magnetic cores, efficient stator windings, and precision rotor geometry reduce energy loss and heat generation, ensuring stable performance under continuous operation.

Design and Engineering of Asynchronous Motors

An asynchronous motor consists of a stator, a rotor, and a durable frame. The stator produces the rotating magnetic field, while the rotor — typically made of aluminum or copper bars — rotates under its influence. The cast iron housing used in DRG motors provides mechanical strength, vibration resistance, and long-term reliability.

These motors are built to IP55 protection standards, making them resistant to dust, moisture, and industrial wear. Combined with thermally protected insulation and high-quality bearings, they ensure stable operation even in demanding environments.

Why IE3 Efficiency Matters

IE3, or Premium Efficiency, motors consume up to 15% less energy compared to IE2 motors, significantly reducing energy bills and carbon emissions. Each DRG IE3 motor is developed and tested to comply with EN 60034-30 European standards, ensuring energy efficiency, low noise, and superior performance under load.

By integrating high starting torque, optimized thermal management, and silent operation, DRG’s IE3 motors offer unmatched value in industrial applications.

Industrial Applications and Benefits

DRG IE3 Electric Motors are used in a wide variety of systems:

-

Pumps – Reliable power for continuous flow systems

-

Compressors – Long-life performance under high load

-

Fans and Blowers – Quiet, efficient air movement

-

Gear-Driven Systems – Accurate torque and speed control

-

Conveyor Lines and Mixers – Consistent power for automated production

Each motor can be customized for shaft dimensions, mounting types, and cooling systems, providing flexibility across industries.

Manufacturing Excellence from İzmir

Izmir’s industrial landscape is home to DRG’s advanced production facilities, equipped with CNC machining centers, automated coil winding systems, and high-precision balancing machines. Every motor is manufactured under strict quality standards and tested before delivery.

Combining local engineering expertise with international innovation, DRG Motor delivers premium IE3-class motors trusted across Europe, the Middle East, and Africa.

Sustainable Power, Reliable Future

At DRG Motor, efficiency is not just a specification — it’s a philosophy. By producing environmentally responsible, high-performance motors, DRG supports industries in achieving sustainable growth. Every motor designed in İzmir reflects a commitment to cleaner energy, durability, and technological excellence.

DRG Motor – Strength in Efficiency, Trust in Engineering.

English

English

Türkçe

Türkçe