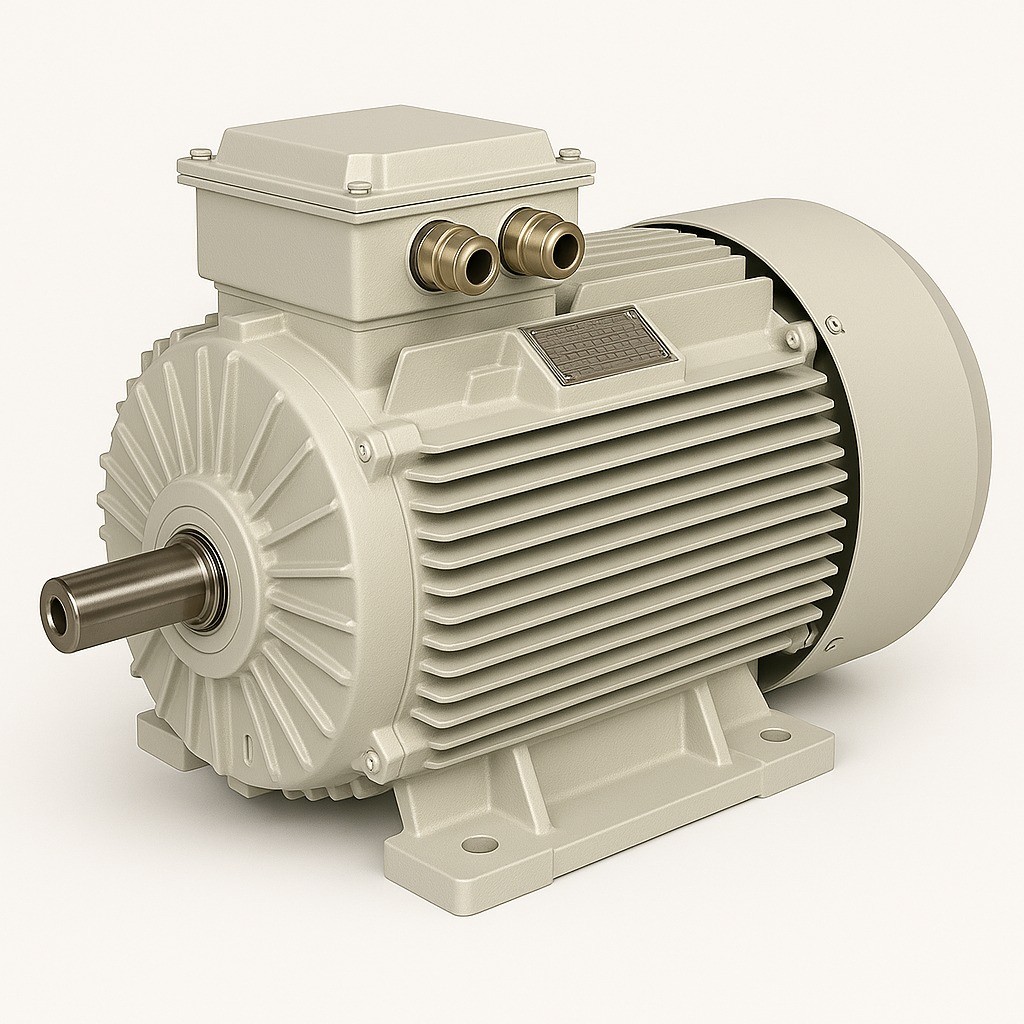

Asynchronous Electric Motor

The asynchronous electric motor is the most commonly used type of alternating current (AC) motor and one of the most preferred motor types in industry. These motors are widely used in heavy industry, production facilities, and daily life due to their durability, simple construction, low cost, and easy maintenance.

Key Feature

The main characteristic of an asynchronous motor is that the rotor speed is not exactly equal to the speed of the rotating magnetic field generated by the stator. The rotor rotates slightly behind the magnetic field; this difference is called slip, which is essential for motor operation. Without slip, the rotor would not start turning. This slip induces electromagnetic forces in the rotor, producing torque.

Types of Asynchronous Motors

-

Squirrel-Cage Rotor Motors:

-

The most common type.

-

The rotor consists of conductive bars short-circuited at the ends to form a cage.

-

Simple design, low maintenance, and long lifespan make it widely preferred in industry.

-

-

Wound Rotor Motors:

-

The rotor consists of windings.

-

Used in applications requiring high starting torque.

-

Rotor windings can be fed through external resistances for start-up and speed control.

-

Working Principle

-

Alternating current passes through the stator windings, creating a rotating magnetic field.

-

This rotating field induces electromagnetic forces in the rotor, causing it to turn.

-

As the rotor speed approaches the stator field speed, the slip remains small, allowing the motor to continuously produce mechanical torque.

Applications

-

Pumps and fan systems

-

Conveyor belts

-

Crushers and screening machines

-

Compressors

-

Industrial production machinery

-

HVAC systems

Asynchronous motors are robust, energy-efficient, and available in various power ratings, making them suitable for both small-scale devices and heavy industrial applications.

English

English

Türkçe

Türkçe